Proper inventory management is a critical factor for the successful operation of any lab. But even though modern labs utilize some of the world’s most advanced equipment, a staggering 85% of labs continue to use old methods for managing inventory like spreadsheets or paper records.

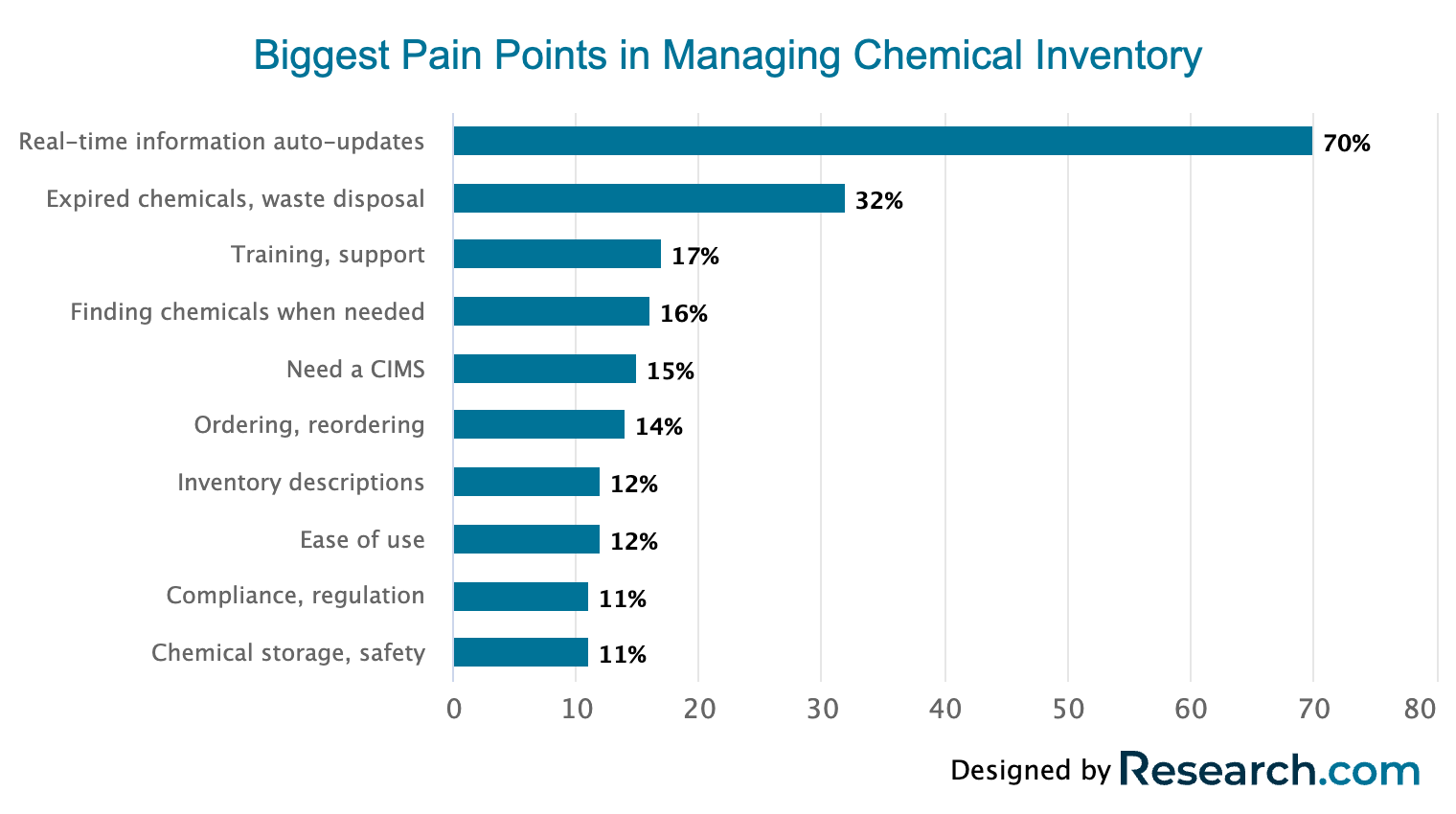

These outdated methods have proven to be inefficient and error-prone, causing significant bottlenecks for many organizations. Manual counting errors, the unavailability of necessary materials for experiments, and sluggish procurement processes all contribute to these challenges. In fact, a 2020 report by C&EN BrandLab stated that the biggest challenge was the absence of immediate updates and automatic notifications about the status and location of necessary chemicals.

Five Benefits of Digitized Lab Inventory Management. Source: Research.com

Not only can inefficient lab workflows hinder research outcomes, but they can also significantly strain lab budgets. It is estimated that the hidden financial impact of suboptimal lab practices exceeds $11B every year.

As the complexity of clinical research increases and the amount of information processed by labs escalates, the need for automated lab inventory management is becoming more and more urgent. By leveraging bespoke digital healthcare solutions for inventory management, labs can benefit in a number of ways, from enhanced inventory accuracy to better accountability and lower costs.

Now, let’s dive deeper into the advantages of lab inventory management solutions.

One of the most crucial features of modern automated lab inventory management is the ability to monitor inventory in real time. As opposed to traditional methods which often involve periodic manual checks, digital systems continuously monitor and update inventory status. They can provide immediate insights into what items are in stock, how much is available, when they were last used, and more.

Think, for instance, of a high-throughput biotechnology lab conducting multiple experiments. With real-time inventory tracking, researchers can quickly identify if there are enough reagents or if they are running low on essential equipment like pipette tips, allowing for timely orders to prevent disruptions. Similarly, in a clinical testing lab, real-time tracking can help technicians identify a sudden increase in test sample intake and order additional testing kits.

In a busy research lab, technicians can spend hours manually entering data about every piece of lab inventory they use, receive, or discard — hours that they could have spent on critical research work. In fact, research by Merck indicated that routine inventory maintenance in a lab can take up to 25% of a scientist’s time.

To streamline data input and enhance operational effectiveness, lab inventory management systems typically incorporate barcode and scanning features. Barcodes can be attached to every item in the inventory, encoding relevant information such as the item’s identity, quantity, and expiration date. With a simple scan, lab workers can quickly and accurately enter data, immediately updating the inventory. In addition, when new stock arrives, instead of manually checking off each item, it can be scanned in bulk. The combination of speed and accuracy translates into significant time savings and much more efficient workflows.

Digitized lab inventory management systems offer advanced data collection capabilities that go beyond mere tracking of in-stock items. Every operation, every usage, and every update in the lab inventory is automatically logged in the system, resulting in a rich dataset. And the value of this data for providing a comprehensive picture of the lab’s operational dynamics is immense.

ML-powered algorithms can crunch through these datasets and identify consumption patterns of different materials, spot the timing of supply depletion, and even predict future inventory needs based on historical data. As a result, lab managers can optimize their ordering process accordingly, reduce waste, or even potentially negotiate better prices with vendors.

Transitioning to digitized lab inventory management can unlock substantial direct and indirect cost savings. Direct savings are seen in areas like labor and inventory costs. With automated workflows, lab technicians no longer need to manually log, track, or search for supplies, which frees up many hours for value-added tasks and research. And by keeping precise track of inventory quantities, lab staff can prevent waste from over-ordering or expiration of materials due to inefficient use.

As for indirect savings, they may not be as easily quantifiable as direct but they are still significant contributors to the overall value. These savings come from reduced downtime or delays due to inadequate supplies as well as informed decision-making and procurement strategy planning based on lab data analytics.

Lastly, a digitized lab inventory solution supports audit readiness by enforcing standardized inventory management procedures. This standardization ensures that all inventory activities are performed consistently, making the audit process more straightforward and predictable. Moreover, these systems are often designed with regulatory compliance in mind, ensuring that labs meet industry-specific standards.

In terms of data security, lab inventory management systems offer robust protection measures to keep sensitive inventory information safe and secure. This strong emphasis on security not only protects valuable data but also meets the high security standards often required during audits.

It is still not uncommon to find labs relying on outdated inventory management methods. But as we deal with increasingly complex scientific tasks, the numerous advantages offered by digitized systems emphasize their practicality in today’s world.

The ability to see your inventory in real time, the efficiency that comes from streamlined operations, the insights gained from robust data analysis — these are not just benefits, they are game-changers. And when you factor in the cost savings and audit readiness, it’s clear that adopting digital inventory management is certainly a practical step in the right direction.

At Kanda, we help healthcare companies and healthtech startups leverage the power of technology to support digital transformation and drive business growth. With in-depth Digital Health expertise under our belt, we have the engineering talent to solve even the most challenging tech puzzles, from automating clinical workflows and health data management to interoperability and regulatory compliance. And being an ISO/IEC 27001-certified company, we guarantee robust protection of crucial information assets for our clients.

Talk to our experts to see how we can help you get your project underway.